Ultrasonic generators

ULTRAPLAST

Ultrasonic generators for intermittent weld applications.

- Robust

- Powerful

- Precisely adjustable

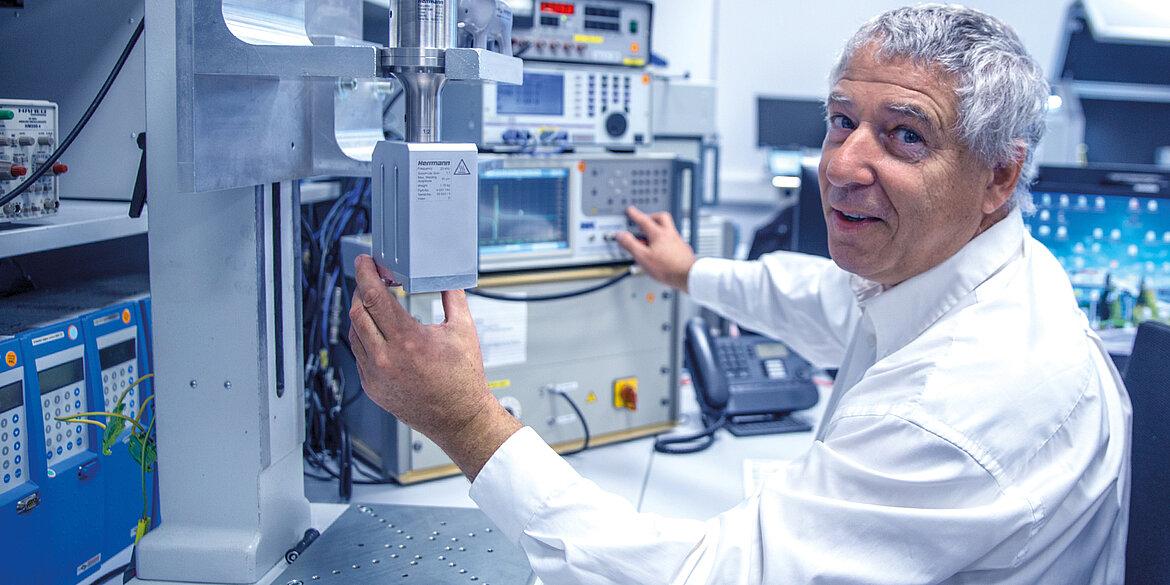

Heavy-duty ultrasonic generators for intermittent applications - The digital ULTRAPLAST product line is available in frequencies of 20 kHz, 30 kHz, and 35 kHz at a power range between 900 W and 6200 W. Programmable ramp up and ramp down times and infinitely variable adjustment of weld amplitudes are only some of the features of this product line. The ULTRAPLAST digital ultrasonic generator is integrated in all Herrmann Ultraschall series machines and systems.

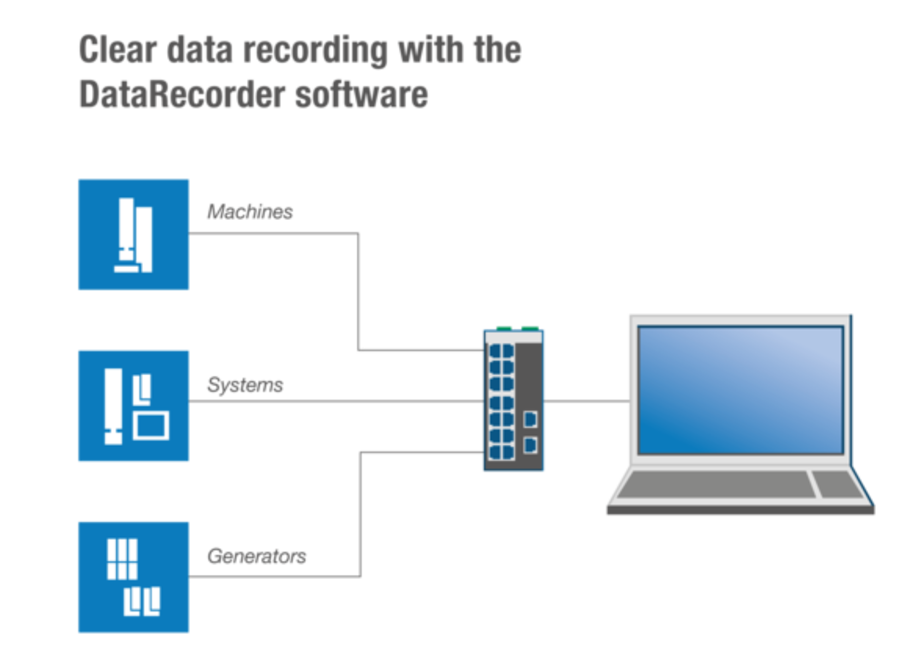

DataRecorder G3

Recording, archiving, and analyzing more than 150 parameters with every weld process:

- Real-time visualization of weld process graphs and trend diagrams

- Communication of status information, measured values, limits, and parameters in MES systems via Ethernet (UDP)

- Export of selected process data and weld graph data into the file system for further processing (CSV, ASCII formats)

- Plug & Record: Connect with the network and simultaneously record process data from up to 16 generators of the ULTRA-X generation

- 100% data safety through continuous recording with monitored data buffering

- Fast navigation through previously archived data

The DataRecorder software can be used with all ultrasonic generators of the ULTRA-X generation.