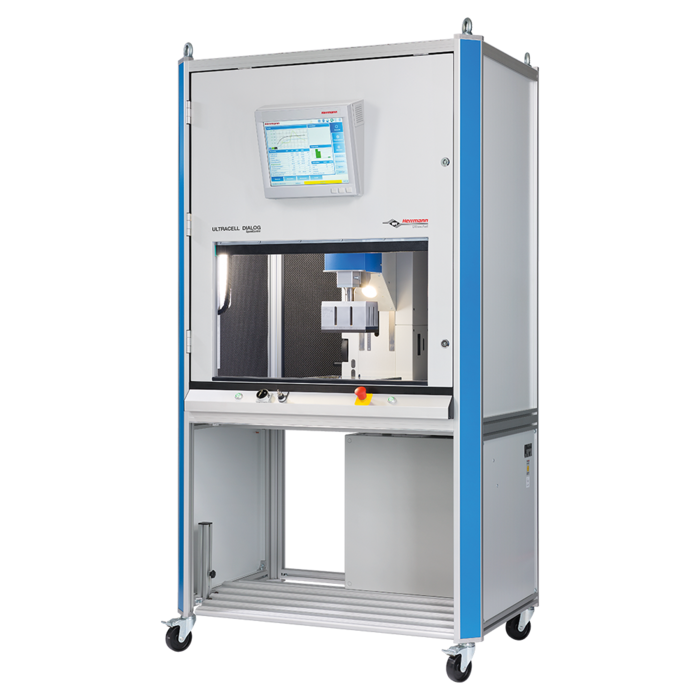

Ultrasonic welding machines for the best joining results

Ultrasonic welding is an especially gentle joining technology for thermoplastic materials and nonferrous metals. Manual work stations are used in many ways in the plastics processing industry. The user manually loads the plastic components to be joined and removes them again from the ultrasonic welding machine after the weld process. The components can be welded with one or more ultrasonic sonotrodes depending on their size and geometry. Partially automated solutions support the work process for the production of high-quality thermoplastic products, but we also offer suitable platforms for copper and aluminum, i.e. for LI battery and cable harness applications. The development and production of all Herrmann ultrasonic welding machines, whether they are series or customized machines, takes place at the parent plant in Karlsbad, Germany.

Advantages of Herrmann Ultraschall welding machines

All ultrasonic welding machines of the HiQ product line, ULTRACELL, ULTRASAFE, punching and sealing machines or ULTRALINE are characterized by:

- Weld process controllers guarantee high joining accuracy

- Development and production "Made in Germany"

- Each machine is subjected to a strict functional and release check (FAT)

- Realization of proven concepts with high technical standards

- All-round application-technical consulting – HERRMANN ENGINEERING

Wide-ranging applications in industry

Ultrasonic welding machines are mostly used in the industries AUTOMOTIVE, CONSUMER, ELECTRONICS or MEDICAL. Particularly where permanently strong, tight and visually impeccable connections are required. With all ultrasonic welding machines, the ultrasonic generators guarantee reproducible results. The weld process is easy to optimize with specially developed controllers and suitable software.