Enhance Softness & Flexibility with Elastic Thread Anchoring

Comfort around the waist and on the leg cuffs can only be achieved using elastic threads or film. These fibers are mostly still fixed using adhesive, which results in high costs and compromised quality.

We have continued to perfect the adhesive-free alternative with ultrasonics called Elastic Thread Anchoring – innovative, yet proven in production. Upgrade your manufacturing now and make your process safer, more economical and more sustainable.

What makes our process so efficient

Save costs, materials, and energy

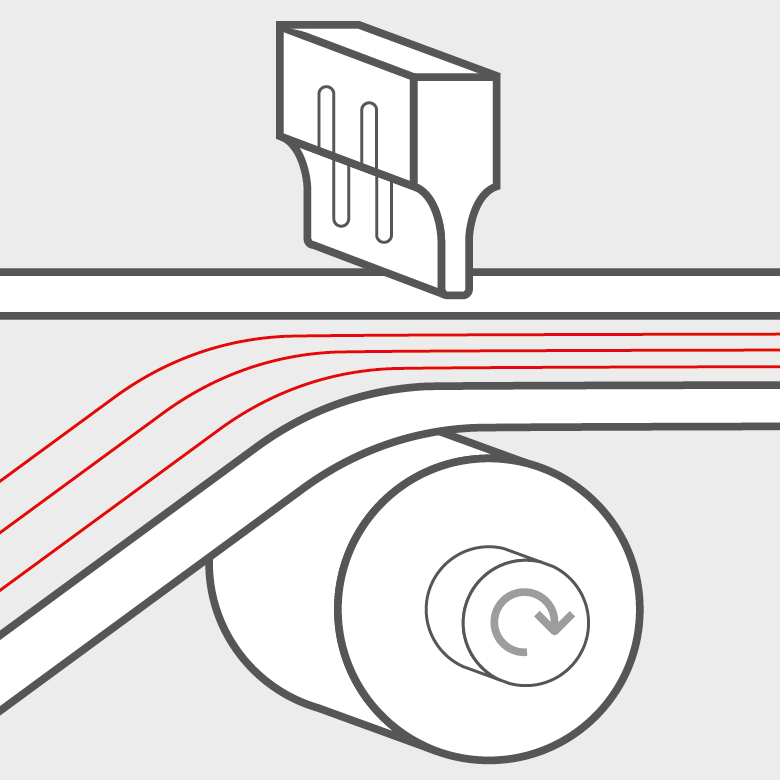

How does it work?

As an alternative to traditional elastic entrapment, the Elastic Thread Anchoring process enables threads to be ultrasonically anchored directly into nonwoven fabric without adhesives or special anvils.

The key to the new process is the Elastic Thread Anchoring (ETA) Sonotrode with a unique surface structure.

The welding tool creates a tunnel through the nonwoven layers for the elastic threads. Depending on the application, specific welding points are created, either continuously or intermittently. In these points, the threads are anchored in the nonwoven material only by means of ultrasonics.

Click on the video to see how our process works!

Saving costs, energy and materials

- Operating costs permanently reduced

- 0% adhesives

- Maximum energy-efficiency

With ultrasonic bonding technology, you can anchor elastic threads sustainably and efficiently: no chemicals, no adhesives, and less thermoplastic material.

Without the costs of purchasing, transporting, and documenting adhesives, companies can achieve significant and lasting savings in operating costs. Energy consumption is also permanently reduced, as energy is only used where it is needed: in the bonding zone of the nonwoven material.

Since the ETA sonotrode is part of a simple quick-change system, it is also possible to reduce downtime and maintenance costs in production.

Consistently high-quality

- Reduced risk of thread breakage

- Flexible material and fiber combinations

- Patented technology

Handling and fixing elastic threads in hygiene products can be complex and expensive – which is why we developed our Elastic Thread Anchoring process. It ensures easy fiber handling, minimal breakage, and a wider process window.

Thanks to the unique geometry of the ETA Sonotrode, it enables the fast, precise and reliable processing of various materials, stretches, and speeds with a single tool.

There is no direct contact between the threads and the welding tool during the entire process, which further reduces the risk of thread breakage.

Boost Softness and Flexibility

- 100% soft

- Very comfortable to wear

- Secure leak protection

A defined shape, soft edges, and strong layer adhesion ensure premium comfort and a pleasant skin feel – without additives, the nonwovens stay soft and smooth. Elastic threads give nonwovens flexibility and function, especially in diaper waistbands and leg cuffs.

Ultrasonic bonding delivers ideal stretch and a perfect fit, as the threads remain unheated and fully elastic.

The result: a soft, high-quality product feel – even when joining natural, recyclable, or compostable materials.

Download Expert Resources

Learn more about the benefits of our ultrasonic bonding technology for your hygiene application. Our downloads contain knowledge from more than 60 years of ultrasonics, providing valuable insights into advanced assembly techniques. By sharing our technical expertise, we foster a close partnership on equal terms, ensuring we can execute projects as quickly and successfully as possible.

Download our exclusive resources to unlock decades of innovation and stay ahead of the rapidly evolving hygiene products industry.

Partner with Us and Reduce Your Operating Costs

Contact our Nonwovens Team to discover how our premium solutions can increase the output of your diaper production while saving up to 90% of your operating costs. We look forward to hearing from you!