Ultrasonics for cuff elastic

Interview with our Head of Applications Development

Ultrasonics for cuff elastic is a relatively new topic. How were they processed before?

Mostly with hot glue, which increases production costs and often causes the diaper material to lose its desirable softness.

What is the most important aspect of thread processing?

It all comes down to the perfect interaction of various aspects: the right gap width between the pins, i.e. the raised parts of the anvil drum; on top of this there is the material grammage in Dtex and thread elongation, and process speed. The thread guiding system is also important and this is where the diaper machine builder comes in: the deflecting angles have to be set carefully and the thread must not touch anything.

Explain your research work in the ultrasonic laboratory to us

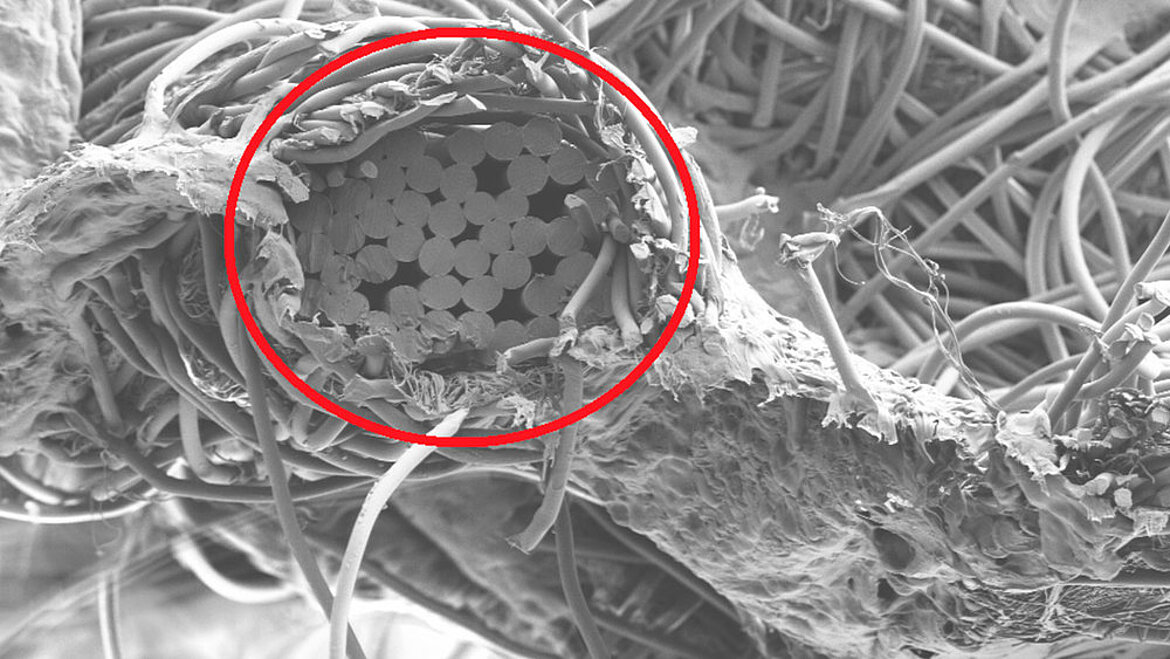

First of all, we wanted to have a better understanding of the structure of elastic threads. We are grateful that the company Lycra provided us with technical information regarding the analysis options and the handling of such threads. Thanks to this we have been able to calculate thread diameters, which is in turn important for developing recommendations for the anvil drum engravings. During our basic work, we took interesting pictures with the scanning electron microscope. Did you know that a thin Lycra thread can consist of up to 55 strings? The REM picture illustrates this very clearly. Through our research work we have also gained a better understanding of creep behavior, which is an important quality criterion for processed elastic threads for diaper manufacturers.

What role does the rotary anvil play?

A very major one, because its engraving is one of the decisive factors in the application’s success. The distance between the pins and the state of the pins play a major role. Our aim is to produce a matrix that recommends the correct anvil drum engraving for each thread.

Where is this trend leading?

In addition to leg cuffs, we are working on the continuous insertion of elastic threads in machine direction in the waist area. The intention here is to use finer threads and finer nonwoven materials to increase comfort. The advantages of ultrasonics over hot glue are clear, because the ultrasonically treated materials feel softer to the touch.